Casting Processes

Pattern Making

click the thumbnails below to view an enlargement • esc clears the enlargement • arrow keys facilitate perusing the images

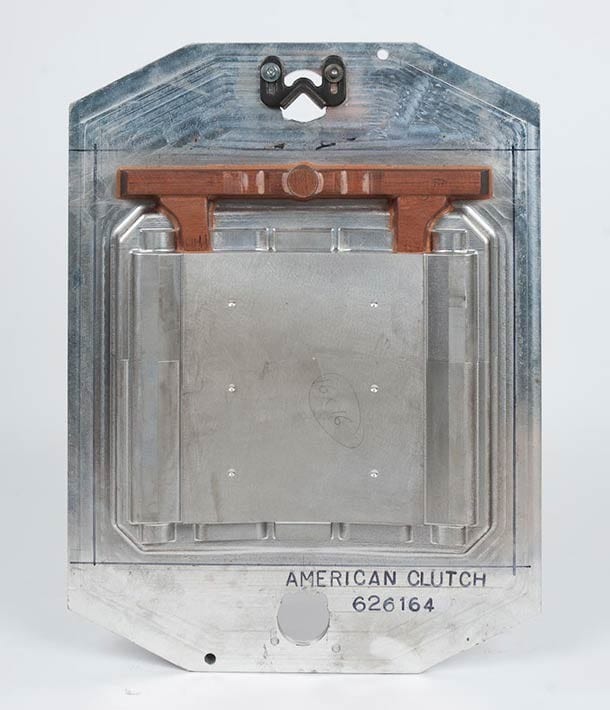

Most patterns are made from mahogany with good production life and wall thicknesses of at least 3/16. An aluminum match plate is required for more complex dimensions and thinner walls with double or even triple the production life of a wood pattern.

Pattern Makers also manufacture the core boxes required (see under Core Making). Shell core boxes can be made in cast iron or aluminum. CO2 core boxes are made in wood.

Patterns are produced by high quality experienced 3rd party companies that we have utilized for many years.

Core Making

click the thumbnails below to view an enlargement • esc clears the enlargement • arrow keys facilitate perusing the images

Three types of cores are manufactured, shell cores, CO2 and nobake cores. Shell cores are the most efficient and economical method of incorporating cores into sand casting molds. The shelf life of shell cores runs into months. CO2 and nobake cores are used either for large castings or for short production runs when the customer does not want the up-front cost of manufacturing shell core boxes and would rather have the cost incorporated into the casting price. The cost is more expensive than shell cores. The shelf life of a CO2 core is very short and the cores must be used within 24 hours of manufacture. Nobake core have an extended shelf life.

Shell cores are manufactured on manual or semi-automatic Dependable Shell Core Machines ranging in size from 100’s to 400’s.

Green Sand Molding

click the thumbnails below to view an enlargement • esc clears the enlargement • arrow keys facilitate perusing the images

Green Sand Molding predominately used in the foundry and it has the advantage of being continually recycled. After each use, the sand is screened, mulled in a Ringmuller and then water added to bring it back to the correct moisture consistency. Smaller castings are molded on numerous lines using BMM Molding Machines. Large castings are molded on the ground and are termed “floor molds”.

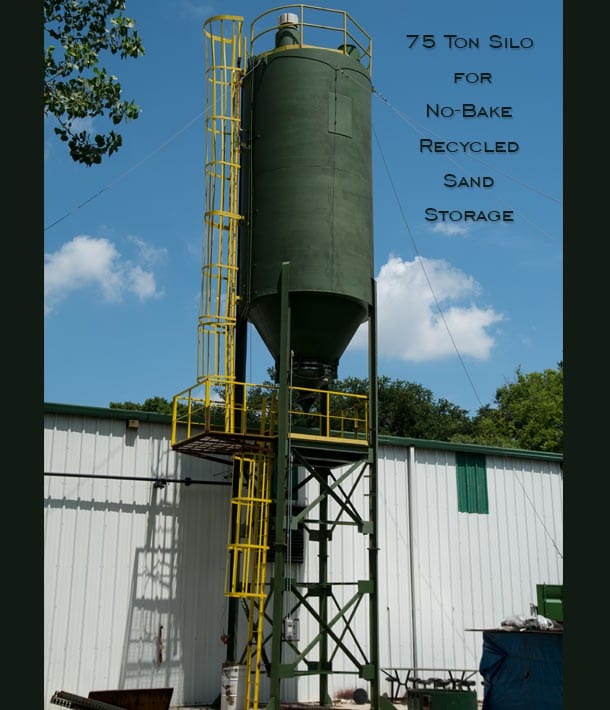

No-Bake Sand Molding System

click the thumbnails below to view an enlargement • esc clears the enlargement • arrow keys facilitate perusing the images

No-Bake molds are expendable sand molds, similar to typical green sand molds, except they also contain a quick-setting liquid resin and catalyst. Rather than being rammed, the molding sand is poured into the flask and held until the resin solidifies the sand, which occurs at room temperature. This type of molding also produces a better surface finish than other types of sand molds. Because no heat is involved it is also known as the airset process because molds are left to harden under normal atmospheric conditions. Common flask materials that are used are wood, metal, and plastic.

Melting – Pouring of Molten Metal

Vibratory Shake-out of Castings

The Inner cores are then removed with a hand held vibratory probe by the molders.

Cut-Off of Excess Castings Metal

Grinding Rough Edges on Castings

All grinding is performed by hand by our expert team of professional craftsman and we stand by our considerable attention to safety as this task is performed.

Casting Finishing Treatments

Rotoblast: Some castings are rotoblasted or shot blasted with small steel shot at the customer’s request for a textured finish.

Vibratory Deburring: Castings are also vibratory deburred to ensure a smooth surface used for most hand tools and wrenches.

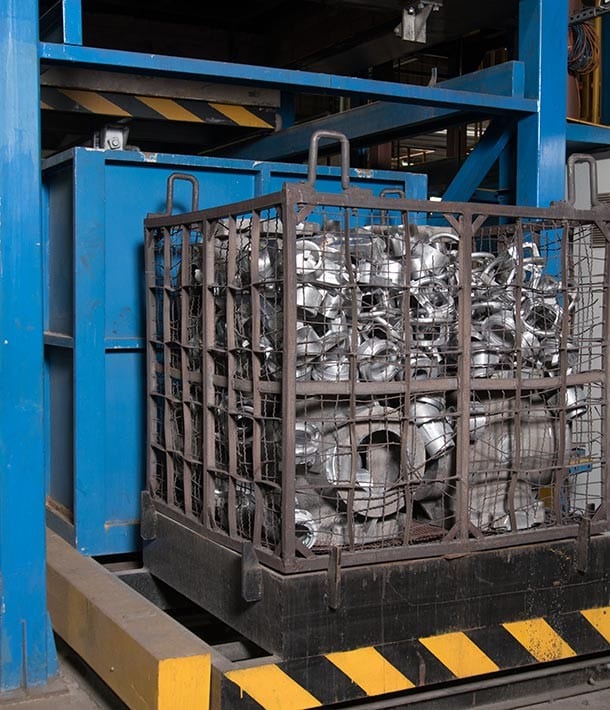

Aluminum Heat Treating

click the thumbnails below to view an enlargement • esc clears the enlargement • arrow keys facilitate perusing the images

Heat treating (tempering) of aluminum alloys is carried out to vastly improve the stability and mechanical properties of aluminum alloys

Coastal Foundry has recently commissioned a new heat treating (tempering) plant at its factory in Houston. The system is designed and equipped specifically for aluminum alloys and can treat up to 2,000 lb. per load. Two separate furnaces were purchased, one a Drop Bottom Solution Heat Treating and the other a Bogie Hearth Aging Furnace. Both furnaces are automatic, are powered electronically with state of the art diagnostics and can maintain temperatures to within + / – 3 ℉, well within the ASTM Standard of + / – 10 ℉. For maximum effect quenching can be done within 15 seconds

Certifications are provided with all products treated. Coastal Foundry is happy to accept contract work. We are happy to be able to provide this as an outside service to a customer requiring T6 treatment of 356.1 or A.356.2 aluminum and T5 aging of 319.1.

Below are the tempering designations:

T5 Age only (precipitation)

T6 Solution heat treat, quench and age

Let Coastal Foundry Company manufacture products for you!